The Spark Plasma Sintering Systems (SPS) is an important tool in the fields of industry and materials research, used for melting and sintering materials under pressure and pulsed electrical current. The primary functions of the SPS system include:

– Sintering and melting materials.

– Creating materials with special structures.

– Reducing sintering time and temperature.

– Researching and developing materials.

– Applications in industry.

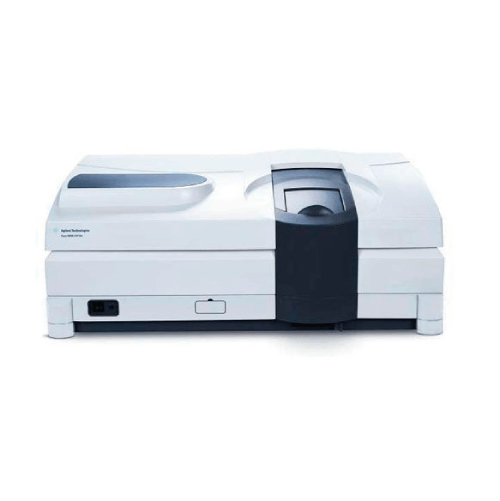

- Model: LABOX-625F

- Manufacturer: Sinter Land Inc.

- Origin: Japan

Reviews

There are no reviews yet.